Delivering the highest quality since 1946.

Airlite Plastics is a privately-held, family-owned packaging company based in Omaha, Nebraska. In operation since 1946, we’ve grown to over 1,100 highly-skilled staff across our six North American locations. In this era of dizzying change and SKU proliferation, we’re the premier partner for North American companies looking to stand out on the shelf.

We’ve built a reputation over time as an innovator. We were ahead of the curve when we released one of the first in-mold labeled containers in 2006 and continue to lead today with our industry-leading portfolio of nearly 50 IML containers.

Our customers in the consumer food and beverage industries benefit from our technology and know-how, which allow us to quickly create imaginative, custom solutions, aligned with industry trends.

Our Locations

Our History

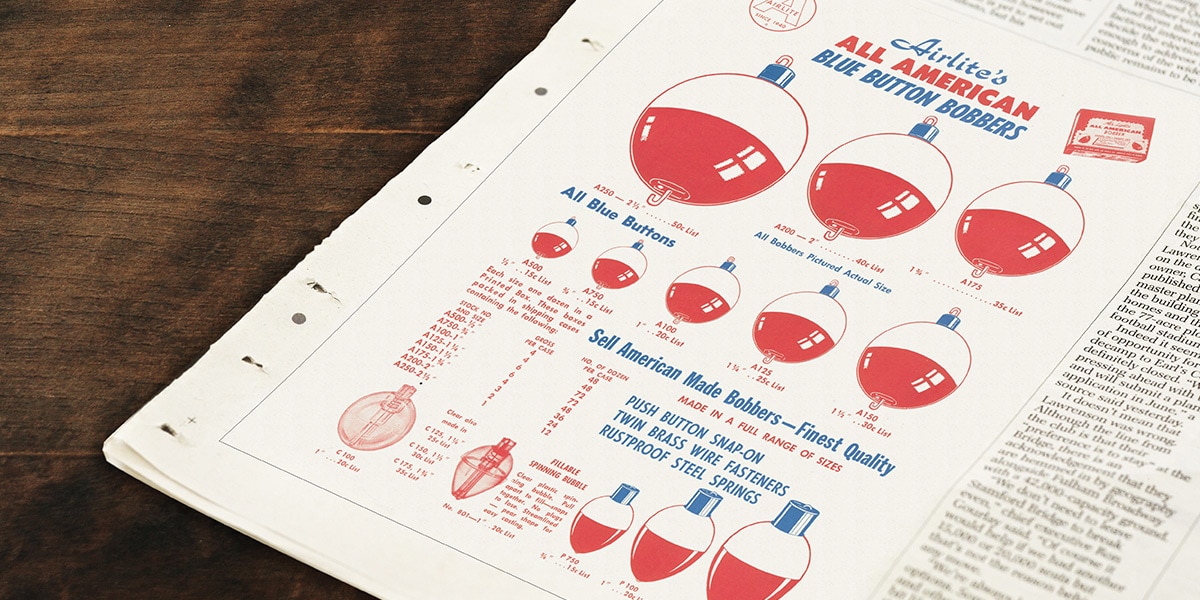

June 24, 1946

The Air Light Products Company, owned and operated by the Lambach family, begins making fishing bobbers one-at-a-time on a single machine in Omaha, NE.

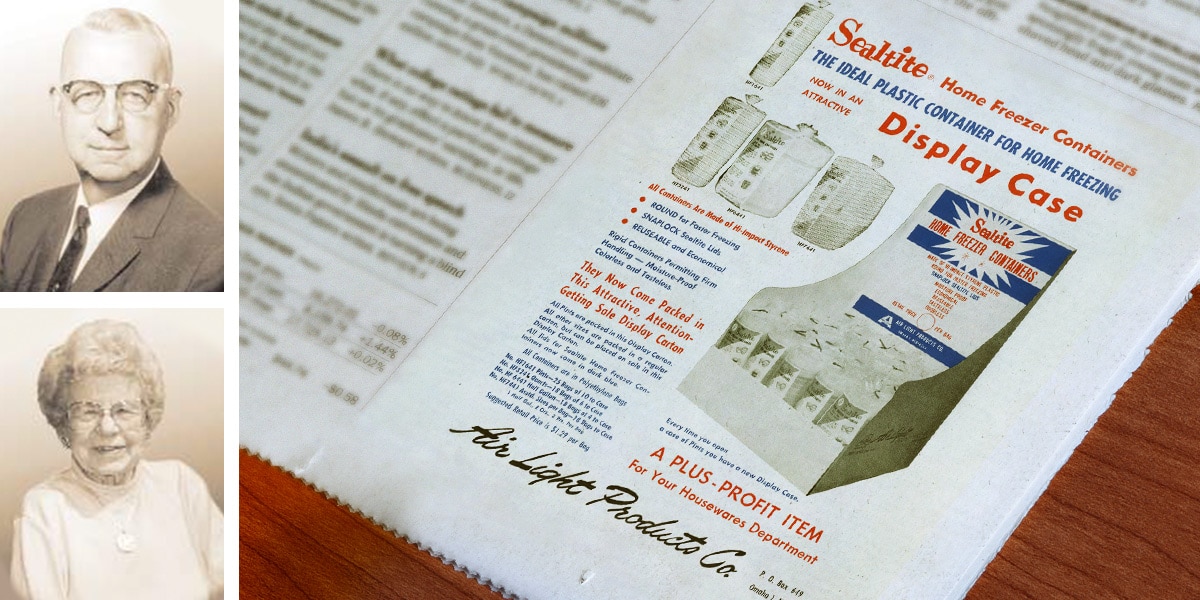

1959 & 1960

Fred and Rose Crosby use their life savings to purchase 50% of the company in 1959 and the other half in 1960. Believing plastics to be the future, Fred immediately expands into food packaging. Together, Rose and Fred are seen as a team with strong vision and Nebraska roots.

1961

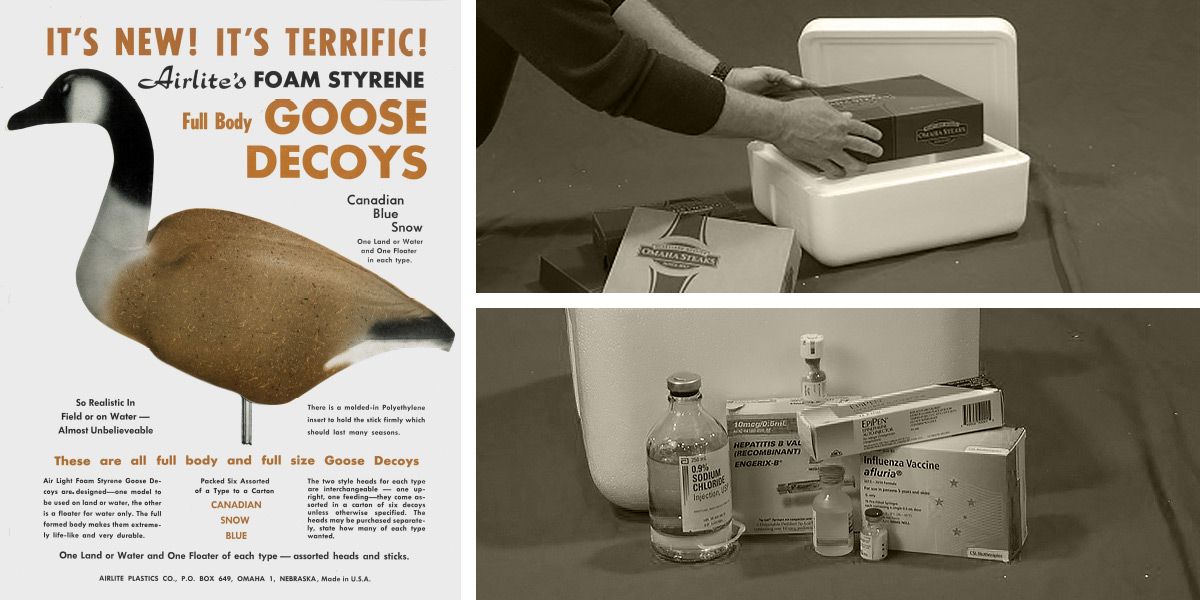

Air Light enters the Expanded Polystyrene (EPS) business. After a fire destroys the building of local company Solar Plastics, Fred purchases their molds as part of his vision to expand the fishing bobber products into a sporting goods line. Years later, the division becomes Arctic Fox® as the focus shifts to creating insulated shippers.

1962

The Air Light Products Company officially becomes Airlite Plastics Company, solidifying the company's future direction in the plastics industry.

1969

Bob Crosby, son of Fred and Rose, becomes President and CEO. Bob is passionate about technology and guided by a simple philosophy: "Just work to be competitive and operate without having fancy, sophisticated overhead."

1978

Airlite capitalizes on groundbreaking technology and begins using LLDPE, or linear low-density polyethylene, to provide lightweight lids for our customer base. This allows us to use less plastic while maintaining product functionality.

1989

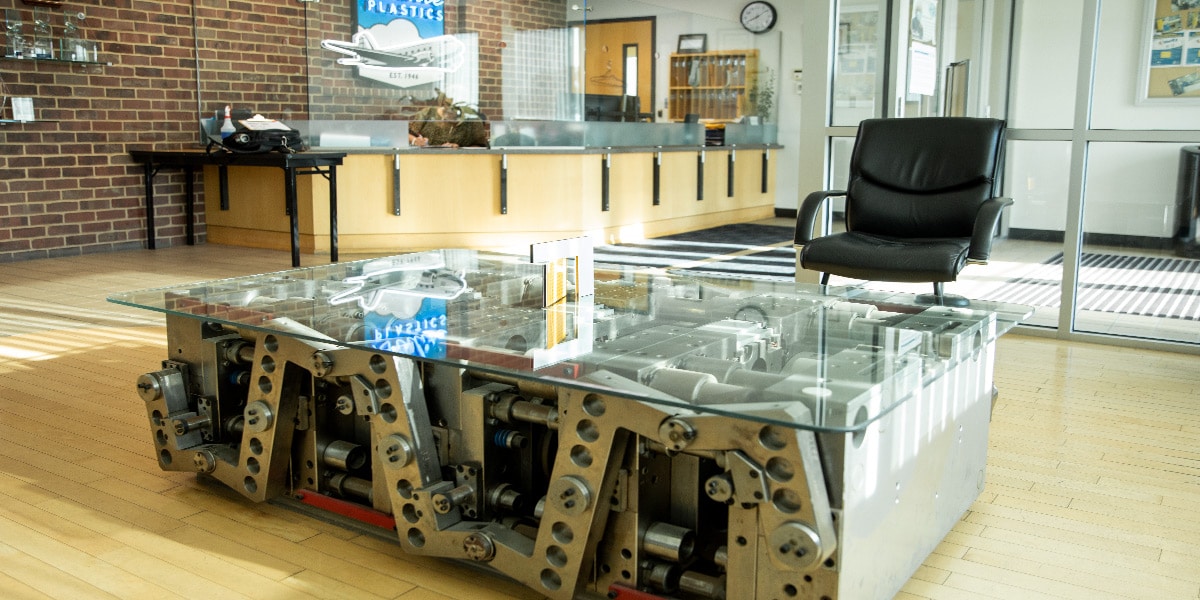

Airlite creates the world's first 4-level stack mold as a lid mold for a 5-quart ice cream container. The four sets of cores and cavities enable Airlite to quadruple production. Today, the 4-level stack mold is still on display at Airlite headquarters in Omaha, where we continue to innovate and build most of our molds.

1996

Brad Crosby, son of Bob and grandson of Fred and Rose, becomes President and CEO of Airlite, and the third generation of the Crosby family to hold that position.

1996

Airlite begins manufacturing insulated concrete forms, or ICFs. Today, Airlite's ICF division is titled Fox Blocks®.

2000

Airlite moves its headquarters to 6110 Abbot Dr., across from Omaha's Eppley Airfield. After years of steady 5-15% annual growth, the company and its now 525 employees had finally outgrown the old location.

2006

Airlite increases the presence of in-mold labeling, or IML, in the United States with the launch of the Blue Bunny 56-oz. ice cream container. This package becomes the first widely recognized IML packaging on shelves in the U.S., helping to spike Blue Bunny's sales by 12.5% that year.

2012

Airlite acquires S&L Plastics. In addition to our synergy with their Measurex® brand tubs, lids, and measuring scoops, Brad also sees the opportunity to expand into the profile and sheet extrusion industries with their Orthoform® and Nylatron® brands. Today, all three product lines are manufactured in our Nazareth, PA facility.

2014

Fox Blocks® ICF acquires select key assets from ARXX Building Products and Reward Wall Systems to expand our product offerings and enhance customer access to innovative green building solutions.

February 2019

Airlite acquires the beverage cup assets from Westgate Products, Inc., drastically expanding the size and style options of the decorated drink cups in our portfolio.

April 2019

The Fox Blocks® ICF division of Airlite acquires TRUEGRID®, adding to our expanding list of environmentally sustainable construction products. The permeable paving grid system is made entirely of recycled high-density post-consumer polyethylene and is designed to help control storm runoff and create less thermal pollution.

August 2019

Airlite acquires cold-chain packaging industry-leader KODIAKOOLER®, and its line of reusable, recyclable, and biodegradable KODIAKOTTON® insulated shippers. Today, the Arctic Fox division of Airlite Plastics now falls under the well-known KODIAKOOLER® name.

2020

Today, Airlite continues its strategy of measured growth and focuses on cultivating a family business's unique culture.

We're a future-first organization

We’re proud of our storied past, but our sights are set on the future. Like you, we believe in ingenuity that benefits the greater good—not just the bottom line.