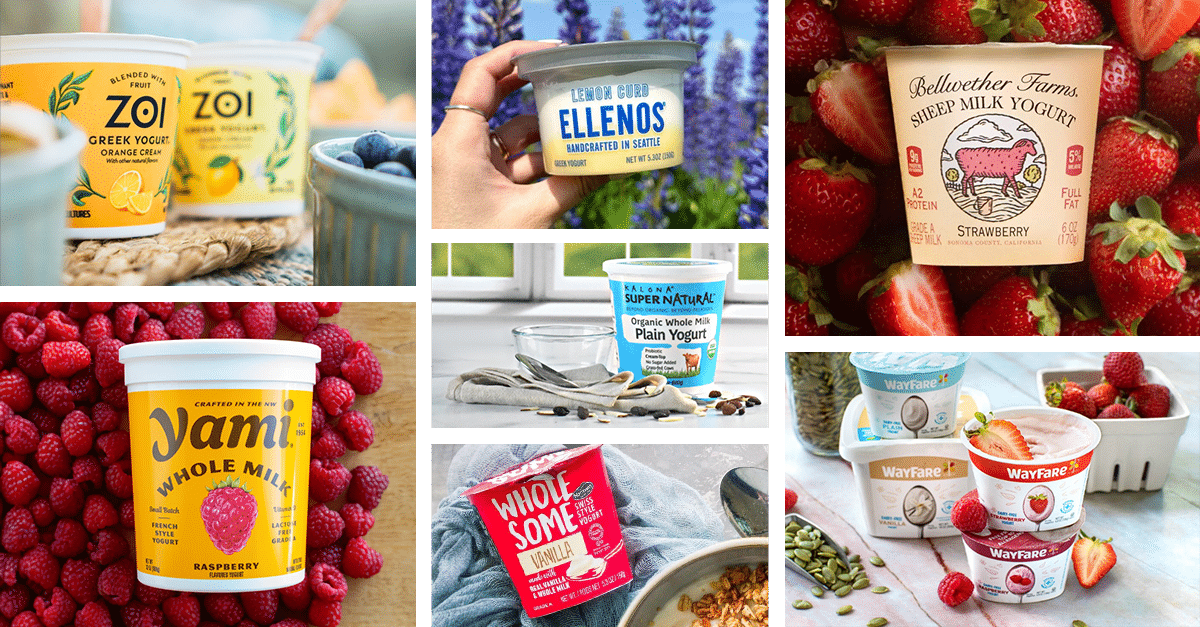

Creating Yogurt Packaging that Stands out from the Crowd

What makes a consumer gravitate towards a specific brand in a category flooded with options? What catches our attention when…

Airlite Plastics Achieves ISCC PLUS Certification: Expanding PCR Options for Our Partners

Airlite Plastics is excited to announce our achievement of ISCC PLUS certification. This significant milestone underscores our commitment to sustainability…

Order Drink Cups & To-Go Containers Directly From the Source

As a small business owner in the food industry, you have a lot to handle each day. Whether you’re running…

Creating Yogurt Packaging that Stands out from the Crowd

What makes a consumer gravitate towards a specific brand in a category flooded with options? What catches our attention when…

Enhancing the Fan Experience with a Premium Souvenir Cup

A trip to the ballpark is an iconic summer tradition. Just picture it in your mind and you can almost…

Why Packaging Matters—The Rise of HPP and Clean Label

Every year brings a growing demand from our partners in the food industry and consumers for safe, healthy, clean label…

Airlite Joins the U.S. Plastics Pact

Airlite Plastics is proud to announce that we’ve officially joined the U.S. Plastics Pact alongside more than 127 businesses, government…

Natural Products Expo West: Bigger and Better Than Ever

This March, our team made the annual trip to Anaheim, California, for the 2023 Natural Products Expo West. It’s one…

Airlite Plastics Acquires National Measures® Scoops

We’re excited to announce that Airlite Plastics has acquired National Polymers LLC, their assets, and their proprietary scoop line. National…

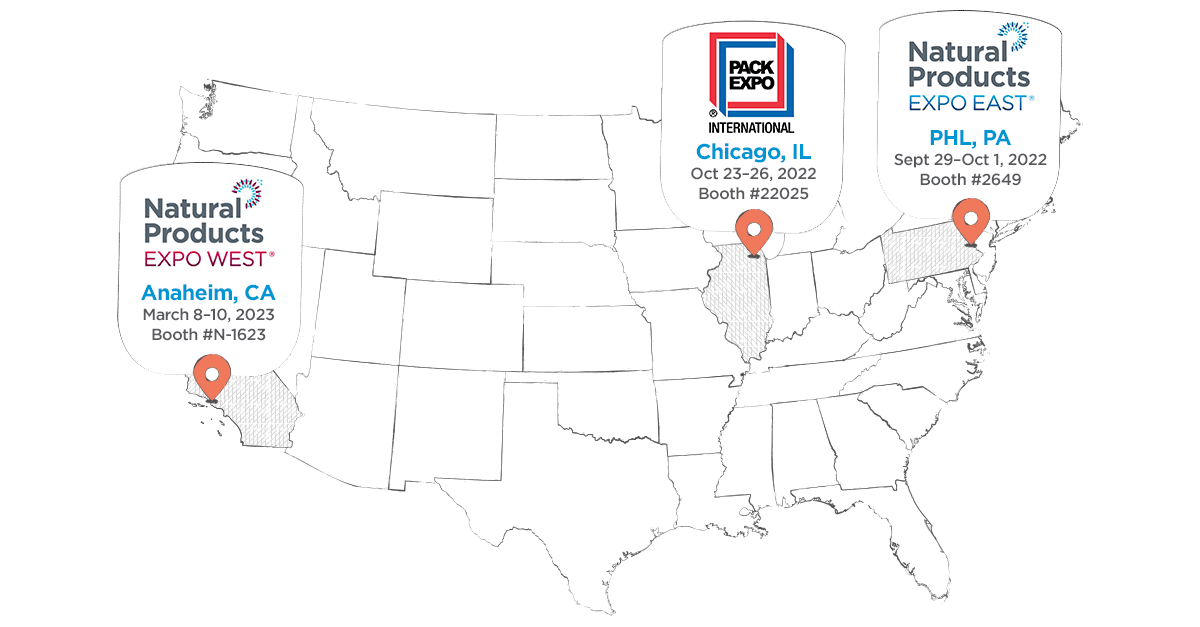

Your Guide to Trade Show Season ‘22-’23

Every year our team looks forward to trade show season. Each show is an opportunity to meet new people, see…

The Impact of “How2Recycle’s” New Polypropylene Labeling

In July 2022, How2Recycle, the North American recyclability labeling system, announced it was upgrading the eligibility of rigid polypropylene…

We're a future-first organization

We’re proud of our storied past, but our sights are set on the future. Like you, we believe in ingenuity that benefits the greater good—not just the bottom line.